Quick-Lock Mounting Brackets for Stage Lighting: Speed, Safety, and Efficiency Compared

RCF AYRA PRO 8 Review: The Best Budget Studio Monitors for Pros?

Quick-Lock Mounting Brackets for Stage Lighting: Speed, Safety, and Efficiency Compared

RCF AYRA PRO 8 Review: The Best Budget Studio Monitors for Pros?

Flight Case Wheels 101: Caster Wheels, Locks, and Materials

Introduction

Transporting equipment safely requires more than just a sturdy case; the right flight case wheels can make all the difference. These wheels come in various sizes, materials, and designs, each with unique performance characteristics. From heavy-duty AV equipment to portable DJ setups, choosing the right caster wheels ensures smooth mobility, equipment protection, and effortless transport.

In this guide, we'll explore how to select the correct caster wheel size based on load requirements, the importance of locking mechanisms for stability and security, the role of springs in protecting equipment from shocks, and the differences between rubber vs polyurethane wheels—and which is best for your needs.

Whether you're handling lightweight gear or high-capacity road cases, understanding these factors will help you maximize performance and durability.

1. Understanding Caster Wheel Sizes and Load Capacity for Flight Cases

Why Flight Case Wheel Size Matters

The size of your flight case wheels directly influences how smoothly your equipment moves across different surfaces. Caster wheels typically range from 2 to 6 inches in diameter. Larger wheels, typically between 5 and 6 inches, roll more easily over uneven surfaces and handle heavier loads. Smaller wheels, around 3 to 4 inches, are better for lighter equipment and indoor use.

The relationship between wheel size and load capacity is crucial when choosing components for flight cases. Many road case wheels use larger sizes for heavier loads, making transport across different floor types easier.

How to Calculate Load Capacity for Flight Case Casters

To determine the correct size, calculate the required load capacity by adding up the total weight of the case and its contents. Divide that number by the number of wheels, then multiply the result by 1.3. This is a commonly used safety factor, but different industries may require different calculations. For example, aerospace and medical equipment transport might call for 1.5 or even 2.0 multipliers to ensure stability and equipment integrity. It’s best to consult manufacturer guidelines for exact recommendations.

If your loaded case weighs 300 kg and uses 4 wheels, divide 300 by 4 to get 75 kg per wheel. Multiply that by 1.3, resulting in 97.5 kg, the minimum load capacity required per wheel.

Wheels for cases like those used to transport aluminum base plates require thoughtful consideration. Specifications like those found in the Flight Road Case that holds six 30"x30" aluminum base plates, available here, illustrate how load distribution impacts wheel selection.

2. Locking Mechanisms for Caster Wheels: Securing Your Flight Case

Types of Locking Systems for Flight Case Wheels

Flight cases often move across uneven or sloped surfaces, making locking mechanisms essential. The right lock prevents cases from rolling unintentionally and helps secure equipment during transport.

There are several types of locking mechanisms that serve different purposes. Total lock casters, for instance, lock both the wheel and the swivel action, which is ideal for cases positioned on inclined stages. Directional lock casters lock the swivel but allow rolling in a fixed direction, which simplifies navigation over long distances.

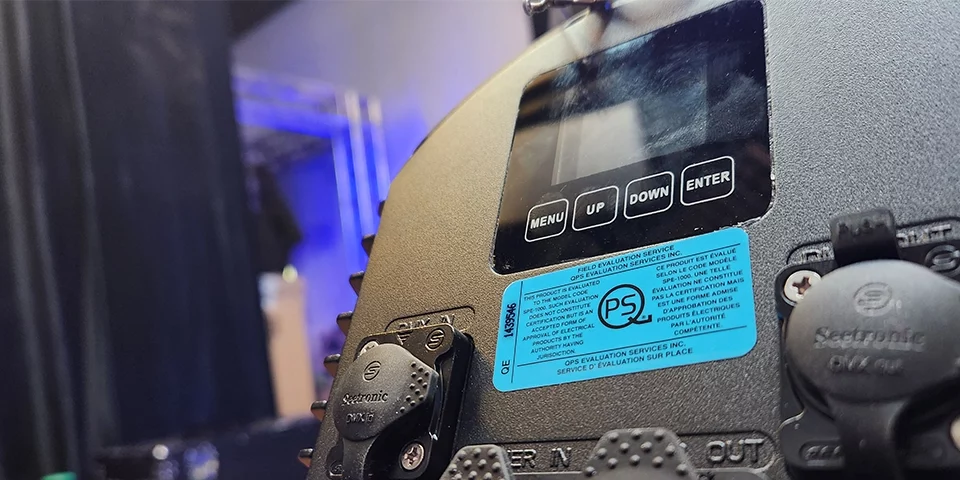

Multi-point locking systems provide enhanced stability by engaging multiple locking points simultaneously. However, their effectiveness varies with design quality, so reviewing manufacturer specifications is crucial. There are many case accessories that can improve the utility of a flight case, such as high-quality locks and durable caster wheels, which you can explore in the Case Accessories section at GTR Direct.

3. Spring-Loaded Casters and Equipment Protection for Flight Cases

How Springs Minimize Shock for Flight Case Casters

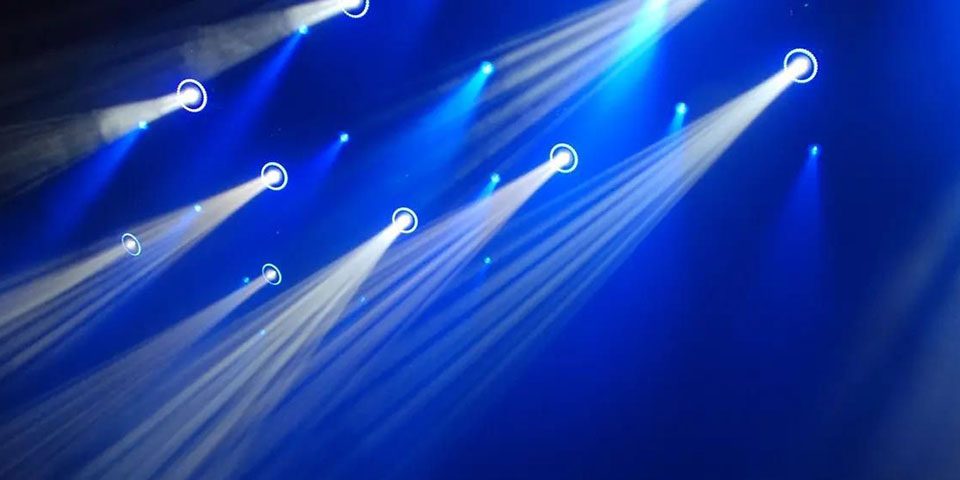

Delicate equipment like audio gear, lighting, and electronics needs vibration isolation during transport. Spring-loaded casters provide shock absorption, reducing the impact of vibrations, sudden movements, and uneven surfaces.

Most spring-loaded casters use compression springs to absorb vertical impact. However, not all models include torsion springs to reduce lateral movement. Models with adjustable spring tension allow wheels to adapt to different load weights.

When transporting fragile electronics, such as microphones or mixers, spring-loaded casters reduce the risk of internal damage. For example, DJ equipment cases often require wheels with vibration dampening to prevent performance issues. The DJ Controller Flight Case Tips article explains more about equipment protection during transport.

4. Polyurethane vs Rubber Caster Wheels: Which Works Best for Flight Cases?

How Material Affects Flight Case Wheels

The choice between polyurethane wheels and rubber wheels significantly affects performance and durability. Factors like durometer (hardness) and environmental conditions influence how each material performs.

| Feature | Polyurethane Wheels | Rubber Wheels |

|---|---|---|

| Durability | High—resistant to abrasion and cuts | Moderate—prone to wear |

| Floor Protection | Safe for hardwood, tile, and concrete (test under heavy loads) | May leave marks |

| Load Capacity | Higher load-bearing capacity | Lower capacity |

| Shock Absorption | Good but firm | Excellent for light loads |

| Noise Level | Quiet with smooth surfaces | Quiet on most surfaces |

Polyurethane wheels are highly durable and resistant to abrasion, making them ideal for heavy equipment and outdoor transport. However, some polyurethane wheels, especially those with low-quality formulations, may mark hardwood floors under heavy loads. Testing on a small, hidden area first is always recommended.

Rubber wheels, especially natural rubber, are more likely to mark floors compared to synthetic rubber. The rubber's durometer rating also influences performance. Softer rubber wheels provide better floor protection but wear out faster. Rubber wheels generally work well for loads under 200 kg, such as guitar cases, microphone stands, and lighting fixtures.

When selecting wheels for flight cases that will face heavy loads or outdoor terrain, polyurethane wheels with high load capacity offer better durability. If you need more insights on wheel options, check out the Case Accessories section at GTR Direct.

5. Matching Flight Case Wheels to Different Applications

The right caster wheel choice depends on how and where you plan to use your flight case. For portable setups that frequently move across smooth event venue floors, smaller swivel polyurethane wheels around 3-4 inches offer a balance of easy maneuverability and solid floor protection.

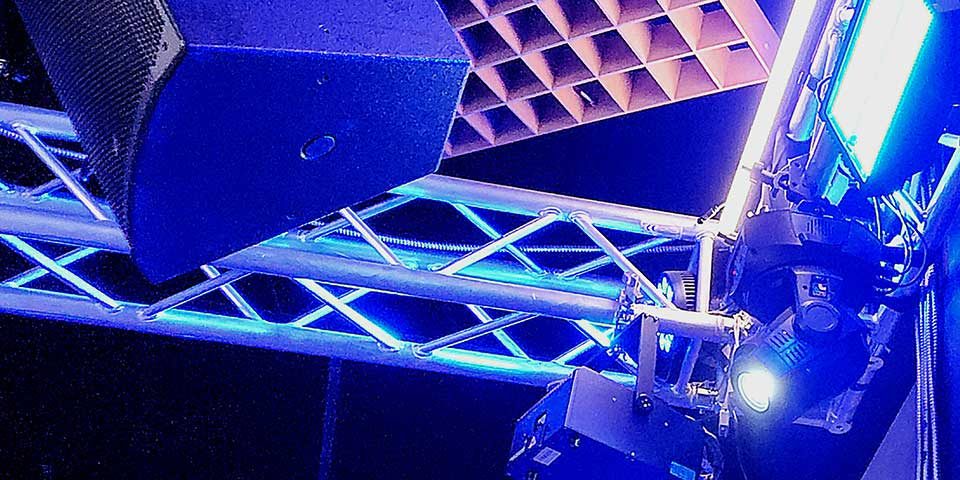

Outdoor festivals or film production sites require wheels that perform well on uneven terrain. Spring-loaded casters with larger diameters, typically 5 inches or more, work best for these scenarios. The spring mechanisms absorb vibrations caused by gravel, grass, and uneven surfaces, reducing the risk of internal equipment damage.

When transporting heavier equipment, consider casters with total-lock mechanisms to secure your gear during transit or when staging the equipment temporarily. Equipment cases designed to hold aluminum base plates or AV gear often benefit from these advanced locking systems.

Conclusion: Choose the Right Flight Case Wheels for Long-Term Reliability

Selecting the right flight case wheels involves more than just size and style. Factors like load capacity, material type, locking mechanisms, and shock absorption play a vital role in how well your equipment is protected during transit.

By understanding these key considerations and matching your wheels to your real-world transport needs, you'll ensure long-term reliability, smooth handling, and protection for your valuable equipment. If you're planning an upgrade or new build, the Case Accessories section on GTR Direct provides an array of components to support your equipment's mobility and protection.